|

|

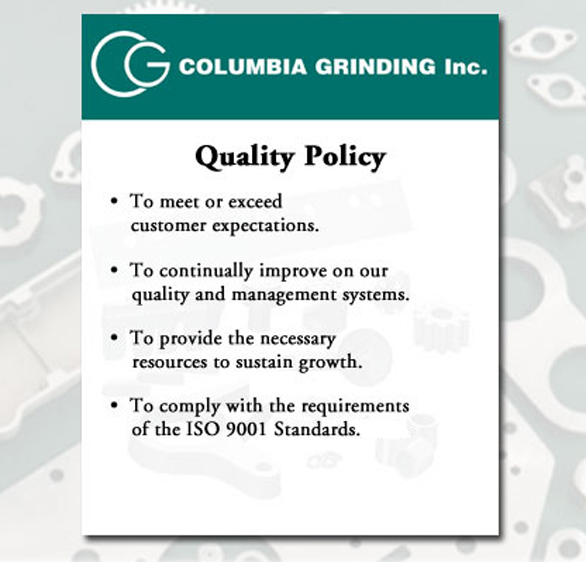

Quality Assurance

We have a full service Quality Lab with a full time hands on Quality Assurance Manager. Our list of services includes but not limited to: SPC, Capability Studies, Gage Studies, Control Plans, PPAPs (Production Part Approval Process), FMEAs, (Failure Mode and Effects Analysis). We keep all of our measuring instruments records in our gage calibration software, traceable to the National Bureau of Standards. We do use SPC as a tool and have data collection stations throughout the shop for our employees to log their readings. Each station contains all the measuring equipment needed. The "Gage Talker Data Collection" system is networked to our Quality Assurance Manager's computer for his monitoring and the storage of data. We can provide certifications as well as data analysis with each shipment if requested to. A particular list of our QC equipment would include: Granite surface plates throughout the shop, some with electronic amplifiers for downloading of data on flatness, parallelism and size.

ISO 9001:2015 - Columbia Grinding Is Certified

We often think of ISO as a quality program, and it

certainly does deal with quality; however, it deals with

management more than anything else. The ISO family

of standards has been developed to assist organizations

of all types and sizes to implement and operate an effective

quality management system. |

Home | About | Capabilities | Whats' New | Rotary Surface | Double Disc | Flat Honing / Fine Grinding

Lapping | Double Sided Lapping | Surface | Quality Assurance | Value Added Services

Contact | Quote My Parts